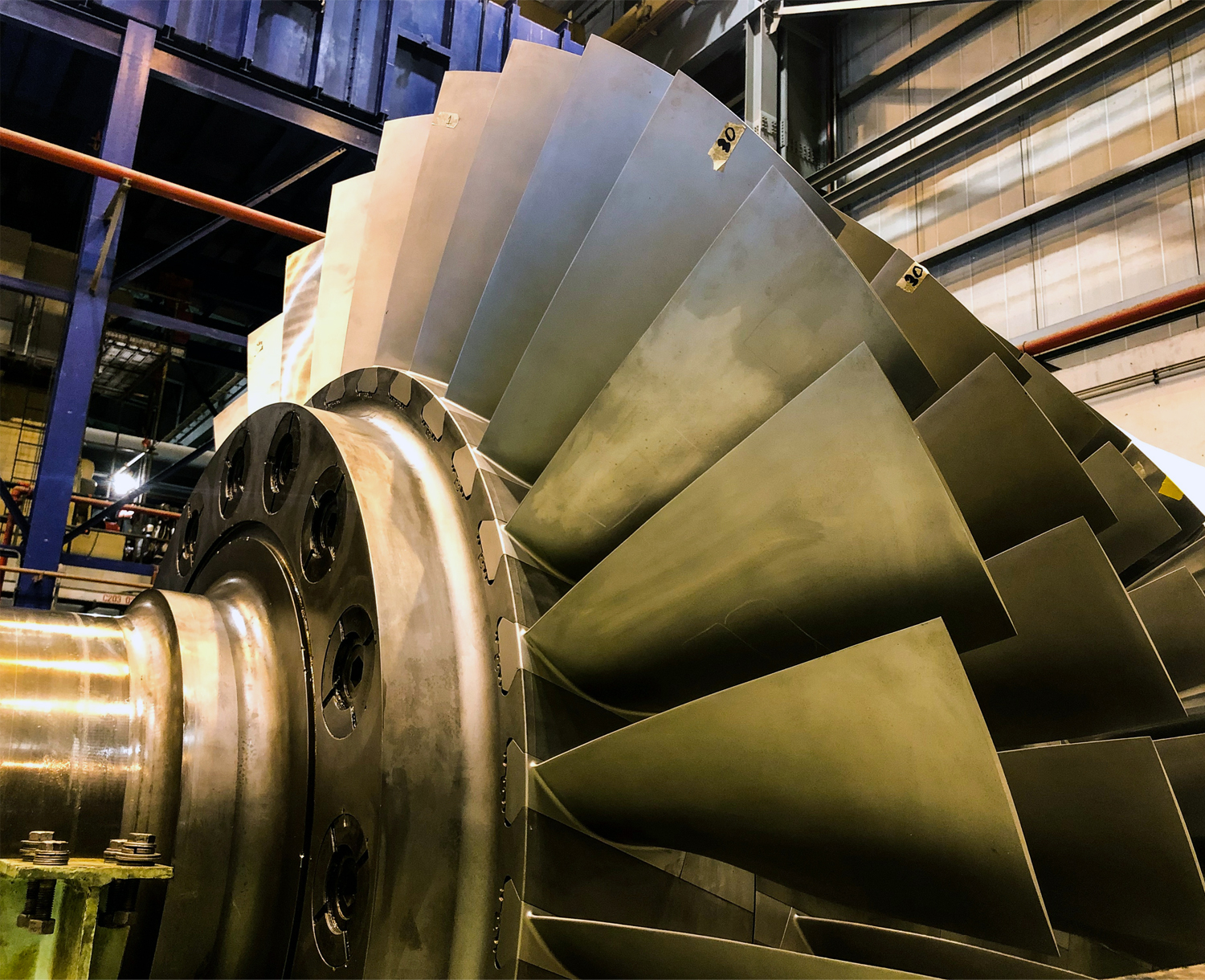

There is new OEM guidance for the GE F Class Fleet concerning the nondestructive inspection requirements of the R-0 and R-1 compressor blade dovetails. Although this inspection is not new, the requirement to inspect the components at the next available outage is an update to the OEM recommendations. The misconception is, that if your R-0 blades have the enhanced undercut design, then the OEM recommendations have been satisfied.

Unless the airfoils have been upgraded with undercut R-1 compressor blades, the risk for blade liberation is still present according to the OEM guidance.

To mitigate this risk, the recommendation is to inspect those affected blades at the next scheduled outage. Veracity performs these inspections in tandem with our borescope inspections.

Veracity’s proprietary UTPA technology allows for the highest probability of detection in the industry which mitigates your risk at the first sign of a defect. In the fall of 2020, Veracity detected a R-1 crack in the dovetail that was near the liberation stage thus preventing a failure of the component. Contact us today for more information or to schedule your next inspection.

Unless the airfoils have been upgraded with undercut R-1 compressor blades, the risk for blade liberation is still present according to the OEM guidance.

To mitigate this risk, the recommendation is to inspect those affected blades at the next scheduled outage. Veracity performs these inspections in tandem with our borescope inspections.

Veracity’s proprietary UTPA technology allows for the highest probability of detection in the industry which mitigates your risk at the first sign of a defect. In the fall of 2020, Veracity detected a R-1 crack in the dovetail that was near the liberation stage thus preventing a failure of the component. Contact us today for more information or to schedule your next inspection.